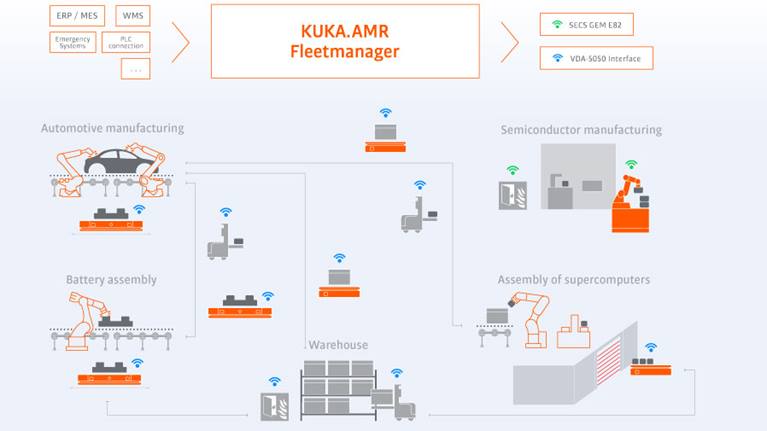

Autonomous transport robots that adapt to your process

With flexible interfaces and the simple integration, KUKA’s autonomous mobile platforms allow for the efficient automation of in-plant transportation. In addition to intelligent features, their strength lies in flexible mobility – thanks to omnidirectional or differential drive technology, they move forwards, backwards, sideways, rotate on the spot and even precisely master curves.

In addition to QR code navigation, KUKA AMRs also have SLAM technology, which simplifies start-up even further. Even in dynamic environments, our AMRs demonstrate their capacity to perform well in complex industrial scenarios using obstacle detection and navigation technology. You can flexibly and safely bypass various challenges such as moving obstacles, people or structural conditions.